The Top-class manufacturers all understand the link between staff knowledge and the production of high-quality parts at the lowest cost.

Only properly trained staff can apply science and technology to the Die Casting process and move to a higher level of capability.

Success is a combination with: Part design optimization, Tooling manufacturing knowledge, Casting machine efficiency and Staff power.

Our 4 training modules will definitively help you to upgrade your TEAM to world class.

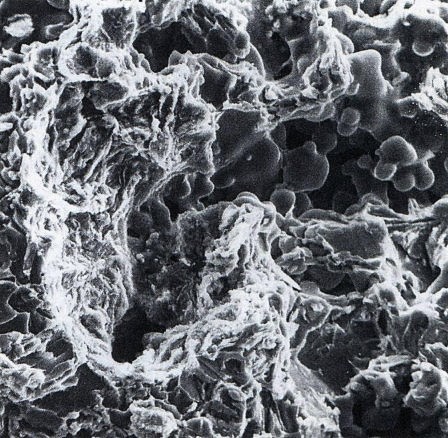

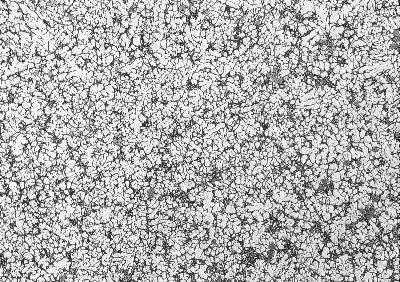

Training module n°1: METALLURGY & IMPLEMENTATION OF THE ALUMINIUM ALLOYS

From the good understanding of the raw material and its composition. Rule of each element in the chemical composition. Melting and holding process. Cleaning and degassing methods. Modification and heat treatment possibilities. Maintenance process of the furnaces.

Training module n°2: DIE CAST TOOLS

Design and calculate an optimised casting shot design including runners, gating, overflows and venting systems. Define and calculate an efficient heating and cooling channel system with part design. Flow and solidification management. Die manufacturing through calculation and best practices. Efficient trimming tools. Maintenance.

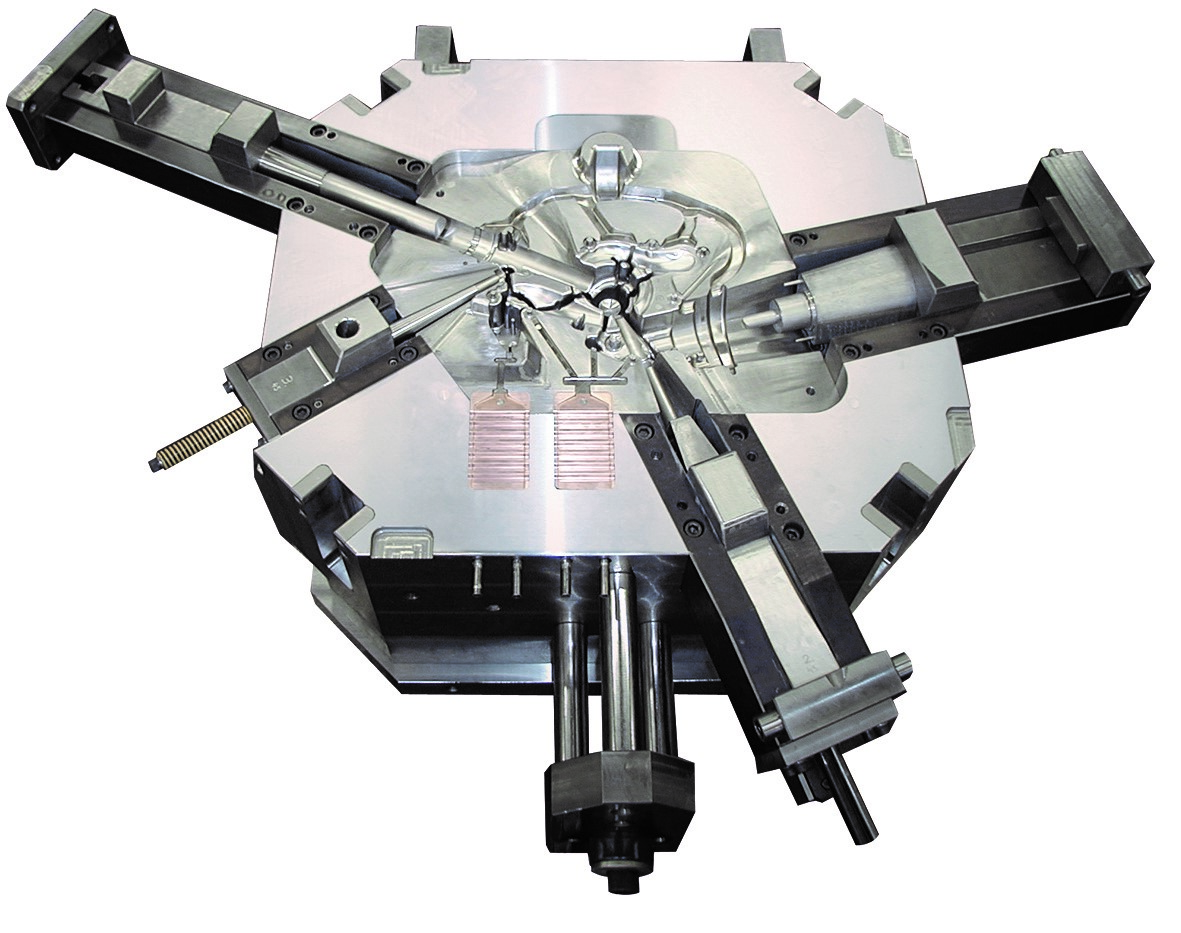

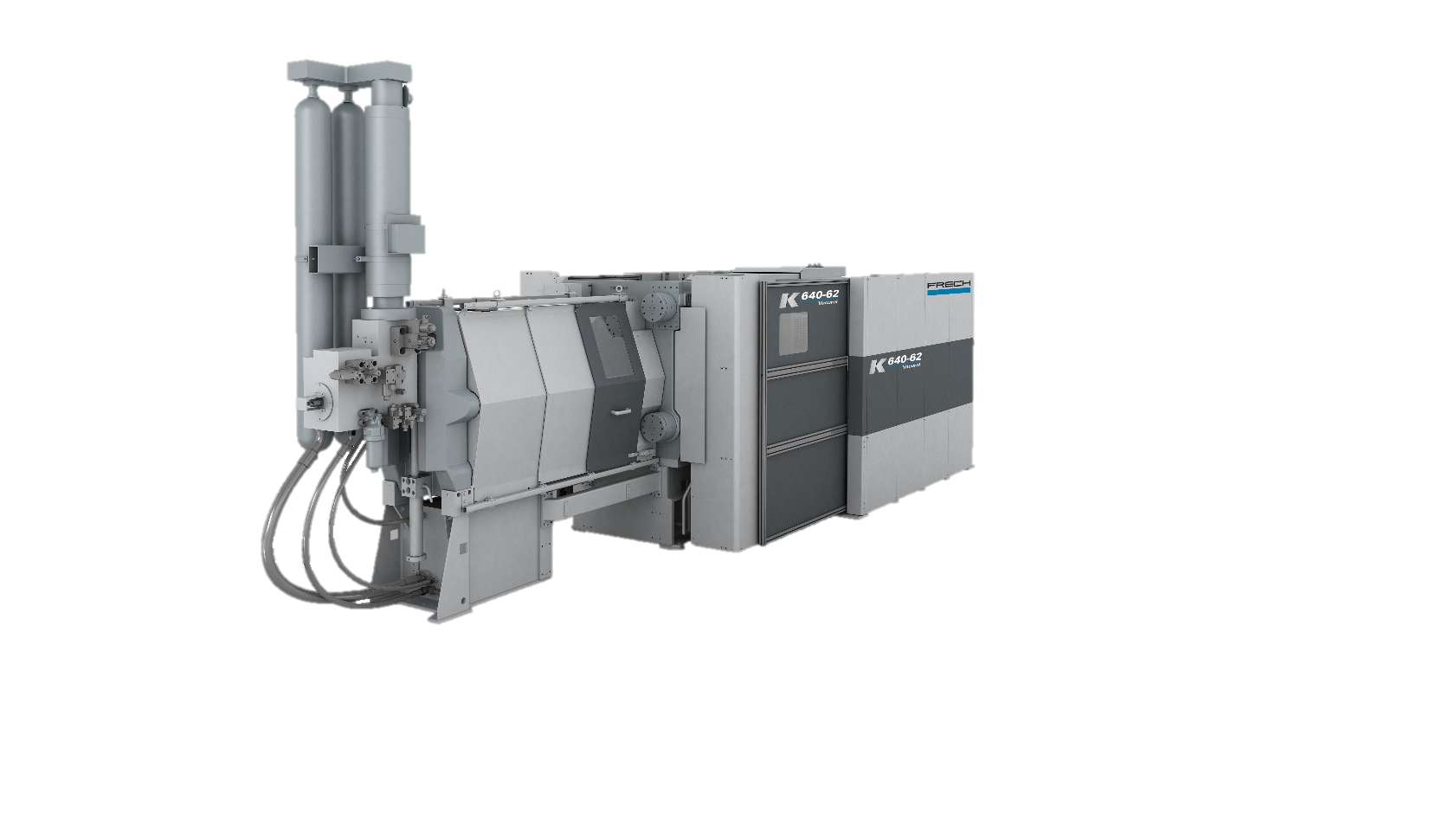

Training module n°3: CASTING EQUIPMENTS

Shape and design of the cast parts, calculation of the machine size required. Casting machine definition and arguments before brand choice. Peripheral devices such as sprayer and metal dosing system. Calculation and optimization of the casting parameters and interpret an injection curve.

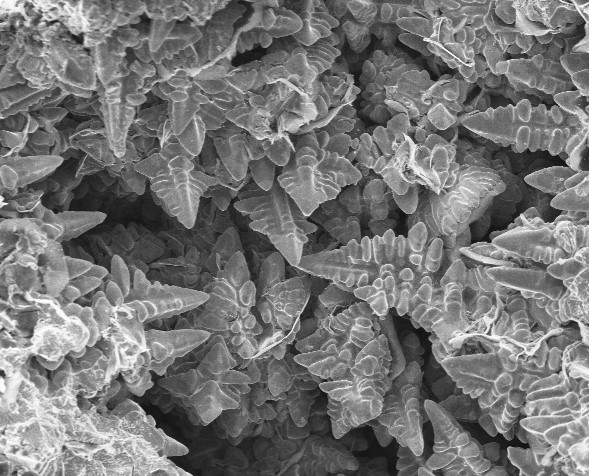

Training module n°4: QUALITY MANAGEMENT

Casting defects identification and eradication. Method of analysis. Quality Management methods. Laboratory equipment’s. Spectrometer for alloys analysis.